| |

|

|

|

|

|

|

|

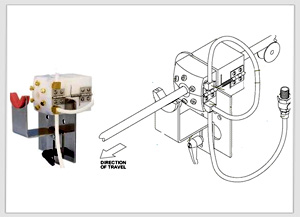

Air Wipe Systems |

|

|

|

|

|

|

|

Drying wire and cable can be

a tricky, expensive

business. AIR JETS AIR WIPES

use precision controlled air

flow to save air, reduce

noise and dramatically cut

energy consumption.

SPLIT OPENING

automatically passes knots

and splices and features

quick-change, bracket and

air disconnects to make size

changes a snap.

FIXED OPENING

features protective ceramic

inserts for bare wire

applications.

RECTANGULAR OPENING

handle strip and other

profiles.

All versions feature very

efficient, economical and

quiet operation |

|

|

|

Drying Cycle :

Wet materials

enters rear of

AIR JETS

AIR WIPE

from a

cooling

through or

quenching

tank. Material

is then

exposed to a

ring of drying

air jets. Dry

material

exists the AIR

JETS AIR WIPE,

aided by an

adjustable

ceramic

centering

guide.

Drying

Theory :

Controlled Air

Flow

|

|

|

|

|

|

|

|

|

|

|

|

Features: |

|

High Efficiency |

|

Design is

based on

the

maximization

of

controlled,

properly

directed

air flow. |

|

A venturi

effect is

also

created at

the

entrance,

further

increasing

air flow. |

|

Uses much

less air

than an

open

pressurized

line or

adjustable

models. |

|

Very Economical |

|

Significantly

cuts

operating

costs vs.

adjustable

or

centrifugal

blowers. |

|

Uses

approximately

0.016

m3/min.

per air

jet at 2.8

bar (0.56

SCFM at 40

PSI). |

|

Extremely Quiet |

|

Low air

flow

provides a

measurable

decrease

in noise

level

output. |

|

Produces

only 75 db

at 3.5 bar

(50 PSI). |

|

Versatile

Applications |

|

Dries

wire,

cable,

plastic,

tubing,

strip and

extrusions

after

cooling

immersion. |

|

Ensures

proper

inspection,

testing,

printing,

packaging

and

storage. |

|

Non Corrosive

Materials |

|

Solid UHMW

polyethylene

bodies,

removable

brass

jets,

non-marking

ceramic

guides,

stainless

brackets. |

|

Custom

Teflon,

stainless

or

aluminum

bodies and

stainless

jets

available. |

|

Critical Sizing |

|

Properly

sized

tolerances

dry

various

products

better

than

adjustable

models. |

|

Quick –

disconnect

air line

fittings

and

brackets

allow fast

size

changes. |

|

|

|

DIFFERENT MODELS: |

|

|

|

|

|

|

|

|

|

|

|