| |

|

|

|

|

|

|

|

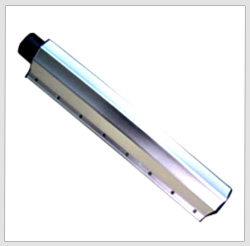

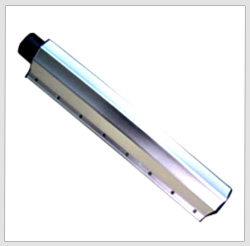

Air

Knife/ Air Blade/Air Wipe Systems |

|

|

|

|

|

AIR KNIFE SYSTEM is a

non contact method of

removing unwanted surface

liquid, moisture, dirt,

coatings, contamination,

debris, heat, static charge

etc during manufacturing

process of predominantly

conveyed (moving) articles

or parts. AIR KNIFE SYSTEM

powered by low pressure air

from blower devices a

continuous LAMINAR SHEET /

STREAM / CURTAIN of

precisely controlled HIGH

VELOCITY AIR. This SHEET /

STREAM / CURTAIN OF HIGH

VELOCITY AIR pushes the

liquid from the surface of

the article / product and

residual moisture is

shattered from the article /

product. This mist is

carried away by continuous

stream of air. This SHEET/

STREAM / CURTAIN OF HIGH

VELOCITY AIR also blows away

debris, clean surfaces,

dissipates heat, spreads /

dries coatings, takes away

static charges, protects

surface etc.

|

|

|

|

|

|

|

|

|